Commercial

INFRaSTRUCTURE

Polyurea has become a transformative material within the infrastructure industry due to its ability to deliver long-term protection, rapid installation, and superior performance in the most demanding environments.

Its spray-applied, fully bonded, and monolithic nature allows complex substrates—such as bridges, tunnels, water and wastewater assets, transportation corridors, containment structures, and concrete rehabilitation projects—to be seamlessly sealed without joints or failure points.

Polyurea’s exceptional tensile strength, elongation, chemical resistance, and abrasion tolerance enable infrastructure owners to mitigate corrosion, water intrusion, freeze-thaw degradation, and chemical attack while significantly extending asset service life.

Read More

With ultra-fast cure times that minimize downtime and traffic disruption, polyurea supports accelerated construction schedules and cost-effective maintenance strategies. As infrastructure systems face increased environmental stress, aging materials, and higher performance expectations, polyurea provides a resilient, low-maintenance protective solution that reduces lifecycle costs and enhances the durability and reliability of critical public and industrial assets.

Roofing System

In commercial and industrial applications, spray polyurethane foam (SPF) and polyurea provide a high-performance roofing solution that outperforms traditional systems. Applied to new or existing roofs, SPF expands to form a seamless, fully adhered insulation layer with high R-value, eliminating thermal bridges and air leaks.

Polyurea adds a rapid-curing, elastomeric, and chemically resistant topcoat, creating a monolithic barrier against water intrusion, corrosion, and substrate degradation. Together, they extend roof life, improve energy efficiency, and deliver a durable, low-maintenance system engineered for the demands of industrial and commercial facilities.

MULTI-STORY PARKING AND PODIUMS

Polyurea provides a superior waterproofing solution for podiums and multi-level parking decks due to its rapid-forming, elastomeric polymer network, delivering tensile strengths of 25–35 MPa and elongation exceeding 350%, far surpassing conventional bituminous or epoxy systems. Its seamless, monolithic membrane exhibits negligible water vapor transmission (<0.1 g/m²·24 h) and bridges microcracks up to 3 mm, maintaining full hydrostatic resistance under continuous water pressure. Polyurea adheres tenaciously to concrete, steel, and composite substrates, accommodating dynamic structural movements without delamination or cohesive failure. It demonstrates exceptional chemical resistance to de-icing salts, oils, and hydrocarbons, alongside high abrasion resistance (ASTM D4060), and retains performance under thermal cycling from –40 °C to +90 °C.

Read More

Fast cure kinetics (<30 minutes to handle) enable immediate load-bearing use, while solvent-free formulation eliminates shrinkage, voids, and cold-weather brittleness. For complex podiums and parking structures, polyurea provides a technically robust, maintenance-free waterproofing system that extends service life and minimizes total lifecycle costs.

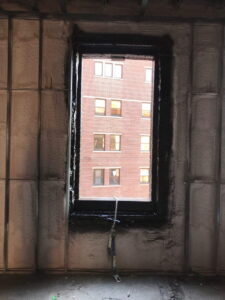

Air Vapour Barriers

PolyAir functions as a high-performance Air and Vapor Barrier (AVB) in commercial construction, providing a continuous, monolithic membrane that replaces traditional blue skin and peel-and-stick systems. Its elastomeric chemistry delivers superior adhesion, tensile strength, and elongation, ensuring long-term integrity under dynamic structural movement. The coating exhibits exceptional resistance to air infiltration and moisture vapor transmission, maintaining airtightness in high-wind and high-humidity environments.

Rated C5 for wind loads up to 329 km/h, polyurea performs reliably across extreme temperature fluctuations, eliminating seam failures common in conventional membranes. Its seamless application mitigates moisture intrusion, reduces condensation risk, and enhances overall building envelope performance, making it a technically superior solution for AVB requirements.

Agriculture

Spray foam and polyurea provide highly effective, technically advanced solutions for the agriculture sector, offering durability, insulation, and protection across a range of applications. Spray foam can be applied to barn walls, silos, and storage facilities to create a seamless, high-R-value insulation layer that controls temperature, reduces energy costs, and protects livestock and crops from harsh environmental conditions. Polyurea, with its rapid curing and chemical-resistant properties, is ideal for lining water tanks, feed troughs, and containment areas, ensuring a monolithic barrier against leaks, corrosion, and contamination. Together, these coatings can be applied to existing structures without extensive demolition, extending lifespan, improving biosecurity, and providing superior moisture, chemical, and impact resistance. The combination of thermal insulation and impermeable coatings also enhances operational efficiency, reduces maintenance requirements, and ensures long-term protection in the demanding agricultural environment.

Poly Jacking

Spray foam slab jacking utilizes high-density polyurethane foam injected beneath sunken concrete slabs to achieve precise elevation and long-term stabilization. Upon injection, the foam rapidly expands, filling voids and consolidating loose subgrade soils, creating a uniform load transfer system between the slab and underlying substrate. Its high compressive strength and low creep ensure the slab remains structurally supported over time, while the foam’s lightweight nature minimizes additional stress on potentially weak or heterogeneous soils.

The closed-cell, hydrophobic structure of the foam provides exceptional resistance to water intrusion, soil erosion, and freeze-thaw cycles, reducing the risk of future settlement. Rapid curing allows immediate serviceability, and the injection process is non-invasive, minimizing disruption to adjacent surfaces and structures. Spray foam slab jacking thus offers a precise, durable, and maintenance-free solution, outperforming traditional cementitious methods in efficiency, longevity, and substrate stabilization, making it ideal for commercial, industrial, and infrastructure applications.